- Home page /

- Journal /

- CTTimes in social media /

- N2 losses during acid stimulations

N2 losses during acid stimulations

Let’s remind that scientific and practical Coiled Tubing Times Journal is an active member of social networks. In particular, the journal has its own page on Twitter (https://twitter.com/cttimesdotorg), a widely known social network that enables users to send and read short messages. On that page one is always able to find links to the most up-to-date news of oil and gas industry and oilfield services. Such an option will be very useful for our readers who often use mobile phones and tablets for surfing the web and accessing the Twitter via a specialized mobile application.

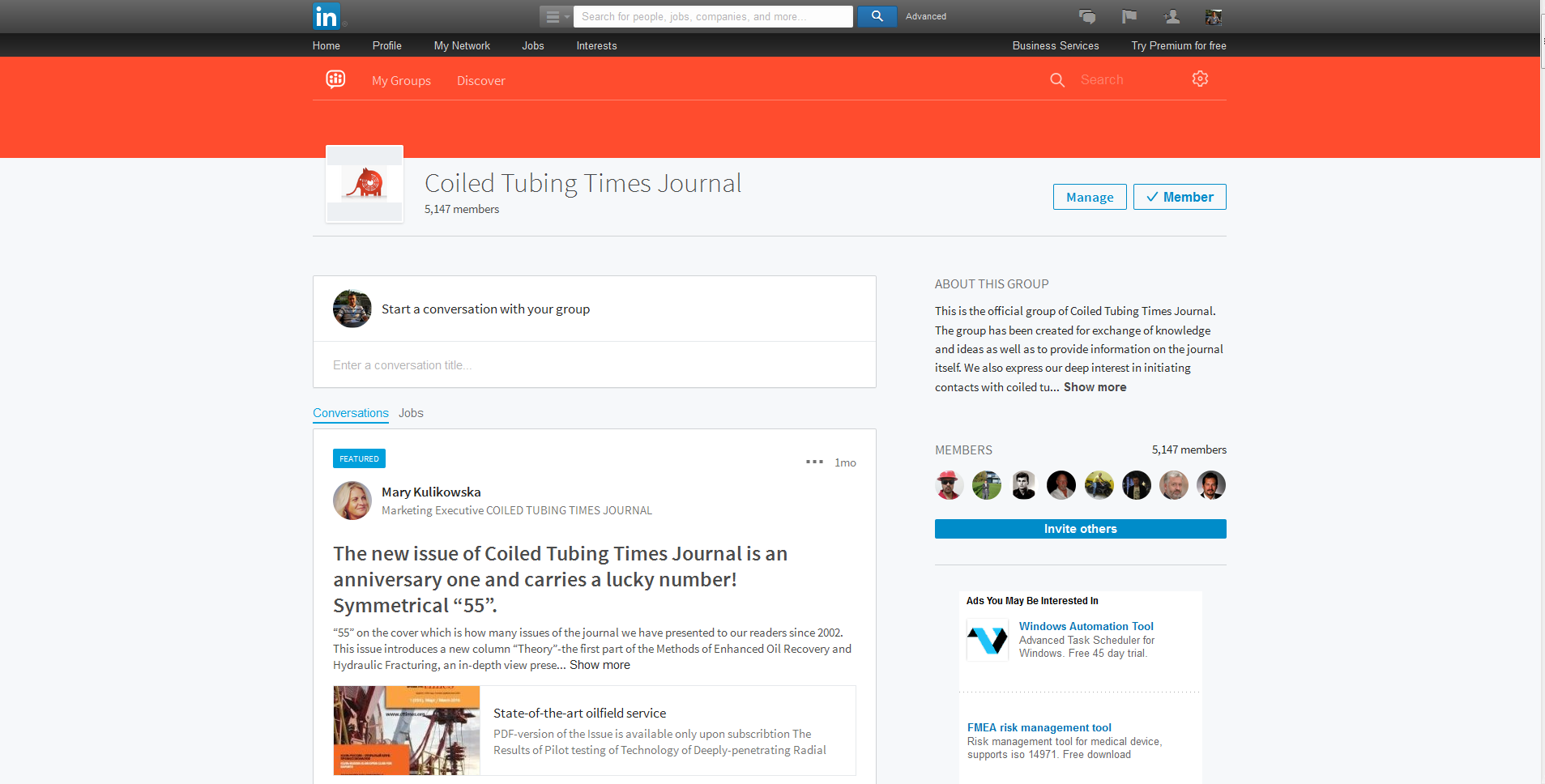

Coiled Tubing Times has its own group on LinkedIn website. LinkedIn is a business-oriented social networking service which allows establishing professional relationships. More than 400 millions of users representing 150 industry segments from 200 countries are registered in the service. The group of our journal (https://www.linkedin.com/groups/2244679) is actively developing and growing in a number of participants. Almost 5,200 users from Russia, USA, Canada, Middle East, Latin America and Asia-Pacific region are currently registered as the members of our group.

LinkedIn social networking service allows not only to establish business contacts and find new friends, but also to find answers to the questions you are interested in. A large number of professionals working in oil and gas industry in general and coiled tubing industry, in particular, are the members of our group. You can always count on that your questions will find the proper answers, and you’ll get the information that will be useful for you.

Coiled Tubing Times continues to publish some of the most interesting and lively discussions started in the Coiled Tubing Times group on LinkedIn. One of such discussions is introduced below.

Abdul Sattar Bugti, Production Engineer at Pakistan Petroleum Limited, asks: “In almost every acid and kick off job almost 500-600 gallons of N2 is being lost during liquid N2 shifting from bowsers to tanks and the pumping unit. How we may reduce this N2 losses during priming and transferring N2 from bowsers to the wellbore?”

Robert Elliott: “It is impossible to have zero losses during LN2 transferring. Ways to reduce losses are: shorten the transfer lines as much as possible, ensure zero leaks at all connections, close in full tricock valve on tank being filled as soon as liquid observed. Can you pump direct from the bowser and take circulated returns from the N2 unit to an empty tank? This will reduce burn off due to tanks becoming saturated. While priming N2 unit, you cannot avoid using approximately 100 gallons to properly prime up, as this is what it takes to displace the air and condition the cryogenic lines. While pumping it is better to pump continuously rather than stop to change over tanks. Have you considered a nitrogen membrane unit where you don't require LN2 on site?”

Raj Chandak: “Use tanks of sizes suitable to your requirement. If the tank is large and volume to be pumped is low, you will have more losses during transportation. As Robert mentioned, prime up loses cannot be removed.”

Eromosele Imoisili: “I might stress that shorter connections are required.”

Abdul Sattar Bugti: “Thank you Robert, Raj and Eromosele for sharing your ideas...”

Packer Prasetiowest: “Check for a leaking connection N2 hose from the tank and N2 liquid line at converter. Before blowing down N2, create pressure at N2 tank of about 0-1 psi to get -196 C to avoid boiling point raising faster than planned. According to N2 theory, if your pump rate is 250-300 SCF you will get high pressure at N2 tank faster. As a result, lots of N2 gas will blow down. When the pressure is 1-5 bar, you will lose 10-16% of the tank volume.”

Fakhr Ul Islam: “All the above comments are very useful. As for me, tank pressure, boost pump pressure, short cryogenic lines, zero leakage are the key things. If N2 operator maintain them properly then the losses will be very little. Also the important thing is the inspection of N2 tank.”

Mlanford Coutinho: “If your ambient temperatures are high (40 to 55 deg C) then you really need good vacuum and insulation in your tank. In spite of that you will have considerable losses... In the middle east at peak summer time you could be lucky if you get 1600 gallons out of a 2000 gallon tank sent from the base.”

Perhaps, comments of these specialists will be useful for the readers of our journal.

By Vasili Andreev, Coiled Tubing Times

Note. The opinions of the above specialists do not necessarily represent the opinion of the Editorial Board.

-

12.10.2022

23th International Scientific and Practical Coiled Tubing, Hydraulic Fracturing and Well Intervention Conference

-

16.09.2022

Exec: Gazprom plans to keep investment program for 5 years

-

24.12.2021

Gazprom Neft, Skoltech and the Khanty-Mansi autonomous okrug-Yugra are developing technologies to produce hard-to-recover oil

-

17.12.2021

Gazprom neft establishes Russia’s first test facilities for developing hard-to-recover oil production technologies