- Home page /

- Journal /

- CTTimes in social media /

- Newly formulated Friction Reducer with Graphite

Newly formulated Friction Reducer with Graphite

Let’s remind that scientific and practical Coiled Tubing Times Journal is an active member of social networks. In particular, the journal has its own page on Twitter (https://twitter.com/cttimesdotorg), a widely known social network that enables users to send and read short messages. On that page one is always able to find links to the most up-to-date news of oil and gas industry and oilfield services. Such an option will be very useful for our readers who often use mobile phones and tablets for surfing the web and accessing the Twitter via a specialized mobile application.

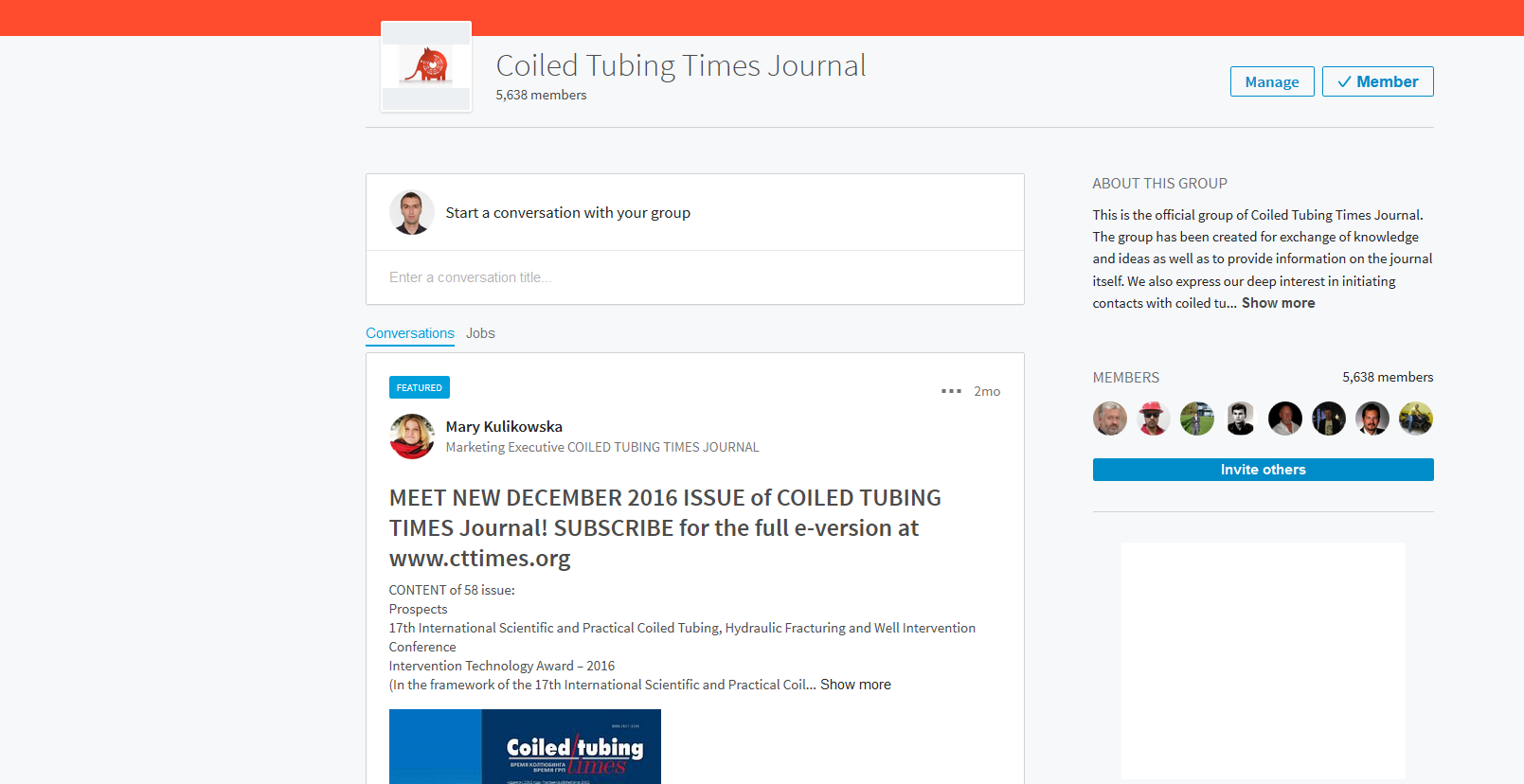

Coiled Tubing Times has its own group on LinkedIn website. LinkedIn is a business-oriented social networking service which allows establishing professional relationships. More than 467 millions of users representing 150 industry segments from 200 countries are registered in the service. The group of our journal (https://www.linkedin.com/groups/2244679) is actively developing and growing in a number of participants. Almost 5,700 users from Russia, USA, Canada, Middle East, Latin America and Asia-Pacific region are currently registered as the members of our group.

LinkedIn social networking service allows not only to establish business contacts and find new friends, but also to find answers to the questions you are interested in. A large number of professionals working in oil and gas industry in general and coiled tubing industry, in particular, are the members of our group. You can always count on that your questions will find the proper answers, and you’ll get the information that will be useful for you.

Coiled Tubing Times continues to publish some of the most interesting and lively discussions started in the Coiled Tubing Times group on LinkedIn. One of such discussions is introduced below.

Ricky Peoples Jr, COO at Peoples Performance Chemicals, says: “Our company, Peoples Performance Chemicals, has recently engineered a new product. We have successfully integrated our graphite product into our polyakrylamide friction reducer (FR). This product has been successfully tested on wells with up to 2 miles laterals. It has drastically reduced pressure and drag. It has been used by several different clients of ours and they have all been very happy with the results. If you're interested in this new FR let me know and I would be glad to send you a sample.”

Alexander Rudnik: “This is a great news! Does this product reduce metal-to-metal friction or hydraulic friction pressures, or both? I'm looking forward to reading an article or a paper about the results.”

Ricky Peoples Jr: “It actually does a really good job of both. We have a study that we are working on getting to put to paper and in an article. As soon as we get it finished I will make sure you get a copy.”

Saeed Pathan: “What is an "equivalent friction coefficient" for this product?”

Mohamad Al-Dujaili: “As Saeed Pathan asks, what is the equivalent friction coefficient, or reducing factor? We are interested in this because we would like to include it in our modelling software.”

Michael Palmer: “Has the compatibility been tested for oil based / water based fluid systems? Are there any comparisons of the performance of this FR against competitors? Have any of your clients used this for drilling applications?”

Ahmed Ezzat: “Good Luck, and Keep Going.”

Ivo Elio Colmenares Cabello: “Could this be used for a concentric coiled tubing such as Sandvac WellVac?”

Otto Miller: “Do you have data comparing your product to other FRs?”

Ricky Peoples Jr: “So far it's just been word of mouth information coming in. We have had our FR on jobs for XTO Energy, Baker Hughes Coil Rigs, Legend Coil Rigs, and a few others. We are very excited about the feedback we've gotten.”

Perhaps, comments of these specialists will be useful for the readers of our journal.

By Vasili Andreev, Coiled Tubing Times

Note. The opinions of the above specialists do not necessarily represent the opinion of the Editorial Board.

-

12.10.2022

23th International Scientific and Practical Coiled Tubing, Hydraulic Fracturing and Well Intervention Conference

-

16.09.2022

Exec: Gazprom plans to keep investment program for 5 years

-

24.12.2021

Gazprom Neft, Skoltech and the Khanty-Mansi autonomous okrug-Yugra are developing technologies to produce hard-to-recover oil

-

17.12.2021

Gazprom neft establishes Russia’s first test facilities for developing hard-to-recover oil production technologies