- Home page /

- New technologies and equipment /

- 3D printing of patterned membranes opens door to rapid...

3D printing of patterned membranes opens door to rapid advances in membrane technology

|

| Courtesy of sciencedaily.com |

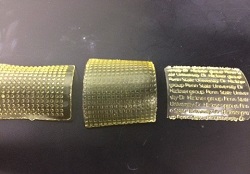

A new type of 3D printing developed by researchers at Penn State will make it possible for the first time to rapidly prototype and test polymer membranes that are patterned for improved performance.

Ion exchange membranes are used in many types of energy applications, such as fuel cells and certain batteries, as well as in water purification, desalination, removal of heavy metals and food processing. Most ion exchange membranes are thin, flat sheets similar to the plastic wrap in your kitchen drawer. However, recent work has shown that by creating 3D patterns on top of the 2D membrane surface, interesting hydrodynamic properties emerge that can improve ion transport or mitigate fouling, a serious problem in many membrane applications.

Currently, making these patterned membranes, also called profiled membranes, involves a laborious process of etching a silicon mold with the desired pattern, pouring in the polymer and waiting until it hardens. The process is both time-consuming and expensive, and results in a single pattern type.

“We thought if we could use 3D printing to fabricate our custom-synthesized ion exchange membranes, we could make any sort of pattern and we could make it quickly,” says Michael Hickner, associate professor of materials science and engineering at Penn State.

The team will continue to optimize the geometry and chemistry of the membranes they print, as well as learn to print new materials, both for membranes and beyond, that have never been printed heretofore.

“We want to bridge the fundamental chemistry and materials science that we do with the engineering and rapid design iterations that the 3D printing industry is really good at,” Hickner concludes.

Source: sciencedaily.com