- Home page /

- New technologies and equipment /

- Alnas Plant Launches Mass Production of New High-Speed...

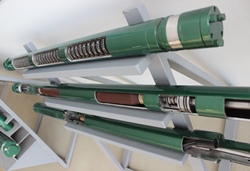

Alnas Plant Launches Mass Production of New High-Speed Thyratron-Motor Pump Unit

|

| Courtesy of rimera.com |

New equipment manufactured by the Alnas Plant has successfully worked away the whole warranty period at Barinovsko-Lebyazhinskoe field, Samaraneftegaz.

The high-speed thyratron-motor pump unit has worked for 365 days constituting the manufacturer’s warranty time. Three new assemblies within the pump unit have been subjected to trial: A Size 3 0615-3 Series pump with capacity of 80 m3/day, a Size 3 thyratron-motor pump with capacity of 50kW and speed of 6,000 rpm, and a Size 3 modular protector with speed of 6.000 rpm.

The equipment has worked in normal operation mode for the whole warranty period, with no loss to technical parameters and power efficiency. No deficiencies have been found during its operation, and the equipment keeps operating at the moment.

The unit is designed for crude production from exploratory wells under intervention, wells with technical constrains and lateral holes. The minimum internal diameter of the casing string is 100 mm.

The 0615ЭЦНАКИ3-80ИТ (0615ETSNAKIZ-80IТ) compression assembly pump features improved discharge and power efficiency parameters. The design deploys single-thrust bearing pumping stages, two-piece assembly made of high-durability solid Ni-resist material, and solid impellers.

The ВЭД50-81-6000М (VED50-81-6000M) electric motor has a high efficiency factor (95%) and true power cosine (0.91), thus cutting the unit’s overall power consumption. The rotor design comprises third-generation magnetic packs; permanent magnets are made of rare earth metals.

The ГТМА3ЛДДЭ ОУ-6000 (GTMAZLDDE OU-6000) modular protector has three levels of protection and uses a reinforced thrust bearing assembly.

“The received Certificate of 365-Day Warranty Operation proves the high reliability of the pump design that fully meets the consumer requirements for power efficiency and high durability. At the moment, as recommended by Samaraneftegaz, mass production of the equipment is being launched,” commented Sergey Sibirev, Director of Rimera Group’s R&D Center.

Source: rimera.com