- Home page /

- New technologies and equipment /

- Halliburton Introduces CoilComm Service

Halliburton Introduces CoilComm Service

|

| Courtesy of halliburton.com |

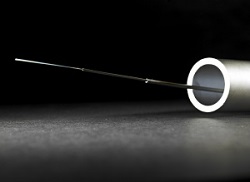

Halliburton’s Production Solutions business line introduces CoilCommSM service to help maximize well production and the success rates of coiled tubing well interventions. The service allows operators to identify which producing zones are benefitting from a stimulation treatment and which are being bypassed by measuring depth correlation and temperature profiles in a single trip down the wellbore. For jetting and underbalanced operations, the CoilComm service allows monitoring of critical downhole data to maintain the coiled tubing and tools within their safe operating envelopes.

Conventional methods of fiber deployment require permanent, casing-conveyed or tractor-in conveyance that can be expensive, limited in depth and risky. In contrast, the CoilComm service provides a more efficient and economical method for continuous, real-time monitoring of horizontal or highly deviated wells by installing the fiber optics inside various sizes of coiled tubing, tailored to the requirements of the wellbore. Tommy Roth, vice president of Production Solutions said “The CoilComm service differentiates Halliburton by offering distributed temperature sensing and downhole data acquisition capabilities with a system temperature rating of 350 degrees Fahrenheit, higher than competing services.”

With CoilComm service, depth can be accurately controlled with the casing collar locator, eliminating uncertainty about where to perforate or set a packer. Temperature related properties such as acid corrosion rates and chemical effectiveness can be maintained within optimum efficiency ranges through real-time downhole monitoring.

The CoilComm service was deployed for an operator in Mexico as part of an integrated coiled tubing solution on a highly deviated well in a carbonate reservoir. The CoilComm service provided ideal conveyance for Halliburton’s StimWatch® distributed temperature sensing service to continuously monitor wellbore temperature across the entire horizontal while pumping a stimulation job. As a result, a thief zone was discovered in real time, the treatment was modified and final acid stages cancelled, saving the operator $120,000 in fluids.

Formerly known as Boots & Coots, Halliburton Production Solutions is a newly formed business line focused on delivering customized intervention solutions to maximize production efficiency and ultimate recovery. Production Solutions comprises several sub-product service lines: Pipeline & Process Services, Pressure Control, and Boots & Coots Well Control and Prevention. Roth said “We are excited about the rebranding of the Production Solutions business line, which more clearly represents our unique breadth of capabilities. Whether it be in deep water, unconventional assets or mature fields, Production Solutions is uniquely qualified to deliver custom solutions around the globe.”

Source: halliburton.com