- Home page /

- New technologies and equipment /

- Halliburton Introduces MaxForce®-FRAC Charges for Improved...

Halliburton Introduces MaxForce®-FRAC Charges for Improved Fracturing Placement and Efficiency

11.05.2012

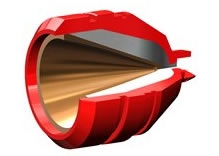

Halliburton has developed a new class of perforating shaped charges designed for perforating oil and gas wells prior to hydraulic fracturing. The MaxForce®-FRAC charge is designed to optimize fracturing efficiency and placement by providing consistency of the perforation entry hole in the casing, regardless of the gun's azimuthal orientation and clearance, which can vary greatly in horizontal wells.

Consistent hole size is an important parameter to ensure that each perforation tunnel contributes equally during the fracture treatment. Injection rates during any stimulation are directly proportional to the perforation hole size; therefore, gun systems with irregular casing hole diameters result in higher-than-necessary injection pressures, and potentially early screen-outs.

Large variation in perforation entrance hole diameters can increase the effects of near-wellbore tortuosity and can leave many of the perforation holes not contributing to the stimulation, causing sub-optimal fluid distribution and higher injection pressures. The MaxForce-FRAC charge provides the tightest variance of the entrance hole diameters currently available, thus improving pressure distribution and stimulation efficiency.

Currently undergoing field trials in the Permian Basin, MaxForce®-FRAC charges have demonstrated up to 20 percent improvement in flow efficiencies, which can reduce the cost and improve the overall success of the fracturing treatment.

The MaxForce-FRAC charge is currently available for 3-1/8-in. and 3-3/8-in. gun assemblies commonly used in 4-1/2-in. and 5-1/2-in. casing.