- Home page /

- New technologies and equipment /

- Nuclear Explosion Technology Adapted for Oil, Gas Seismicity...

Nuclear Explosion Technology Adapted for Oil, Gas Seismicity Monitoring

|

| Courtesy of teknoblog.ru |

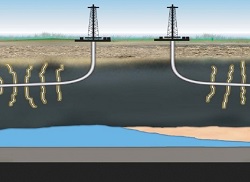

GeoEMS Energy Monitoring Systems, has been providing operators with seismic monitoring technology that can monitor hydraulic fracturing and waste water injection, writes Rigzone.

The company’s technology has been adapted for oil and gas monitoring from technology initially developed for the U.S. Department of Energy and the U.S. Air Force to monitor nuclear explosions. GeoEMS provides seismic field monitoring for oil and gas fields, carbon dioxide sequestration, geothermal fields, volcano monitoring, and for seismicity monitoring and slope stability for underground and open pit mines.

The company’s standalone system identifies and reports induced seismic activity back to an operator in near real time. The time to relay information back is typically less than three minutes, using the system’s onboard processing capabilities. Information is relayed through email or text alerts to an operator and a pre-determined list of employees or relevant third parties.

“Nobody can predict earthquakes, but the technology allows us to provide daily or monthly reports to operators so they can see what kind of seismic activity is taking place in the vicinity of their injection fluid facilities,” said Dr. Steven Taylor, chief scientist with GeoEMS, in an interview with Rigzone.

Shutting in wells to address high-volume injection can cost a company $100,000 to $200,000. “What we try and do is provide large and small operators with an inexpensive means of complying with government regulations.” Taylor, a seismologist who retired after a career working at the U.S. national laboratories Lawrence Livermore and Los Alamos, and his partners used a Small Business Innovation Research Program to develop their business.

SBIR enabled them to build the system for government purposes, but also encouraged them to go out and market the product and create jobs. To qualify for an SBIR, numerous commercialization forms must be filled out, indicating the commercial applications of a product.

In the United States, there are very few documented earthquakes from hydraulic fracturing itself, and these are typically small. However, the story is different in Canada, where the fact that hydraulic fracturing is causing many of the felt-earthquakes is well-documented. One of the company’s deployments has bene for a coal-methane field, and the company expects to start monitoring soon at a CO2 sequestration site.

Source: rigzone.com