- Home page /

- New technologies and equipment /

- PowerDrive Archer RSS delivers high speed with increased...

PowerDrive Archer RSS delivers high speed with increased angle

09.04.2012

E&P companies are turning to complex well trajectories as they strive to hit distant targets, intersect fractures, penetrate multiple fault blocks, and reach deeper into reservoirs. Although these often highly convoluted directional wells can be difficult to drill, they increase wellbore exposure to the pay zone and improve reservoir drainage efficiency.

Choosing between high build rates or drilling speed

For years, steerable motors were the tools of choice for directional drillers. Drilling mud supplied power to these motors, which achieved high build rates at the cost of lower drilling speeds. Subsequent development of the rotary steerable system (RSS) let drillers build angle with a higher rate of penetration (ROP), but at lower build rates and dogleg severities (DLS).

Getting the best of both worlds

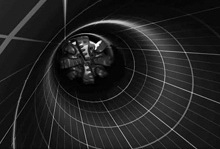

The tradeoff in selecting either a steerable motor or a rotary system has always been wellbore angle versus ROP. However, Schlumberger recently addressed this problem with the introduction of the PowerDrive Archer RSS. The new system has demonstrated an ability to attain high DLS while achieving the ROP typical of an RSS. Just as importantly, it is a fully rotating system—all external tool components rotate with the drillstring to enhance hole cleaning while reducing the risk of sticking.

The PowerDrive Archer rotary steerable system has been used in a wide range of onshore and offshore environments, from the US to the Middle East and Australia.