- Home page /

- New technologies and equipment /

- Saudi Aramco Energy Ventures Announces Equity Investment...

Saudi Aramco Energy Ventures Announces Equity Investment Into Zi-Lift

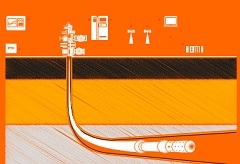

It is currently developing three products: TorqueDrive, targeting heavy oil production and gas well deliquification including conventional and unconventional gas wells; SpeedDrive, targeting retrofit conventional oil wells; and KickStart, for kill fluid displacement as an alternative to coil tubing/nitrogen lift.

Zilift’s high power density products can be deployed using coil tubing or wireline deployment techniques, while delivering power efficiency and optimized production. When available, the tools will also reduce lifting costs, enabling customers to explore innovative progressive cavity pump (PCP) and electrical submersible pump (ESP) deployments in situations and applications where none exist today.

Following three years of development, the Zilift TorqueDrive for PCP system is undergoing qualification testing.

Ibrahim Buainain, CEO, SAEV, said: “Reliable and easily deployable artificial lift systems are a priority area of technology development for Saudi Aramco. We believe that Zilift’s technologies offer potential for substantial time and cost savings in artificial lift deployment and the potential for substantially enhancing the output from large numbers of producing wells. We are delighted to become an investor in the company.”

Iain Maclean, CEO, Zilift, said: “Artificial lift has a long established history of technical development, however, significant step changes are infrequent. In contrast, Permanent Magnet Motor and Transmission technology has made significant advances in the past twenty years, driven predominantly by significant increases in magnet material performance to enable smaller machines with high power density.”